Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

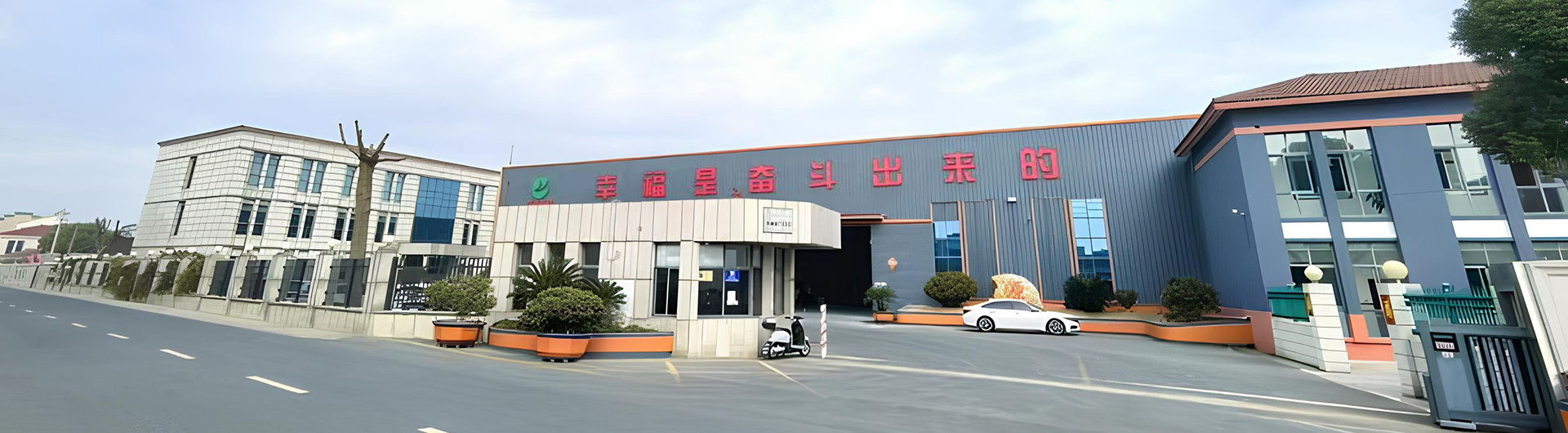

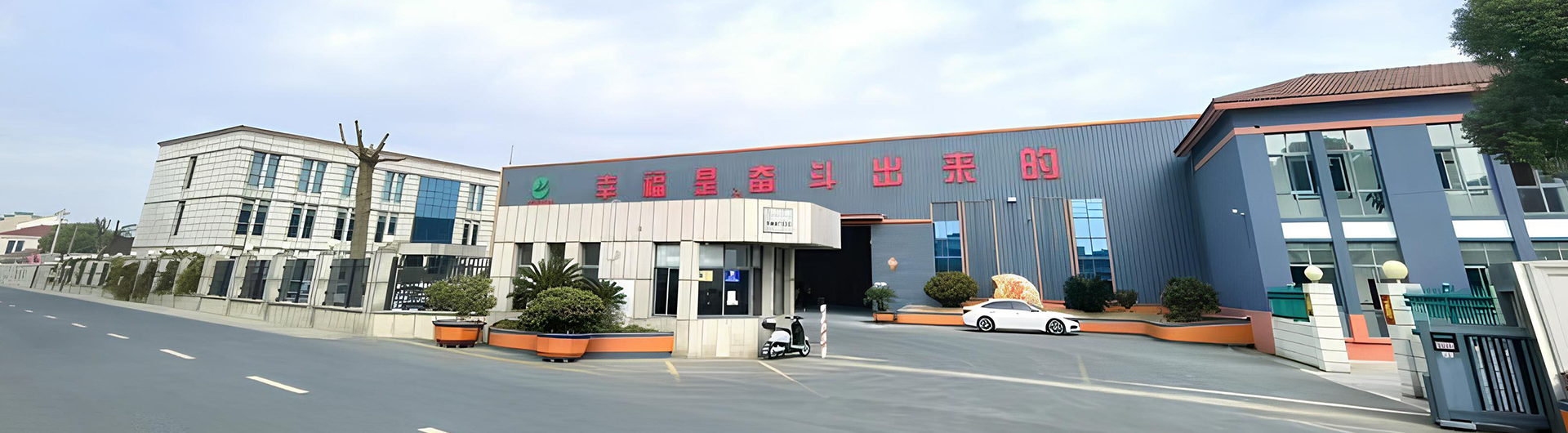

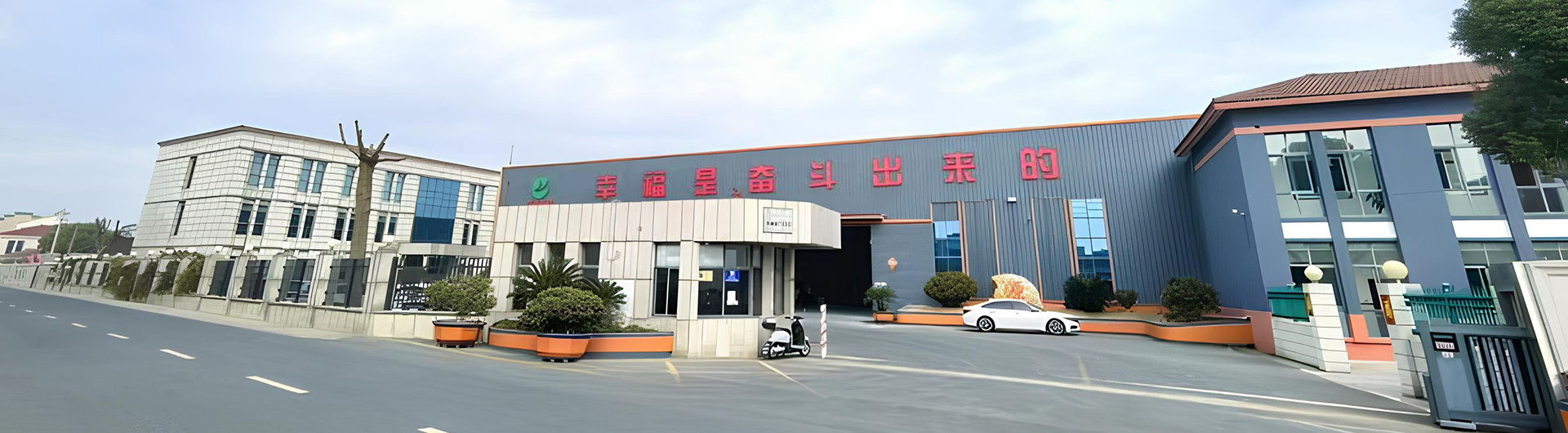

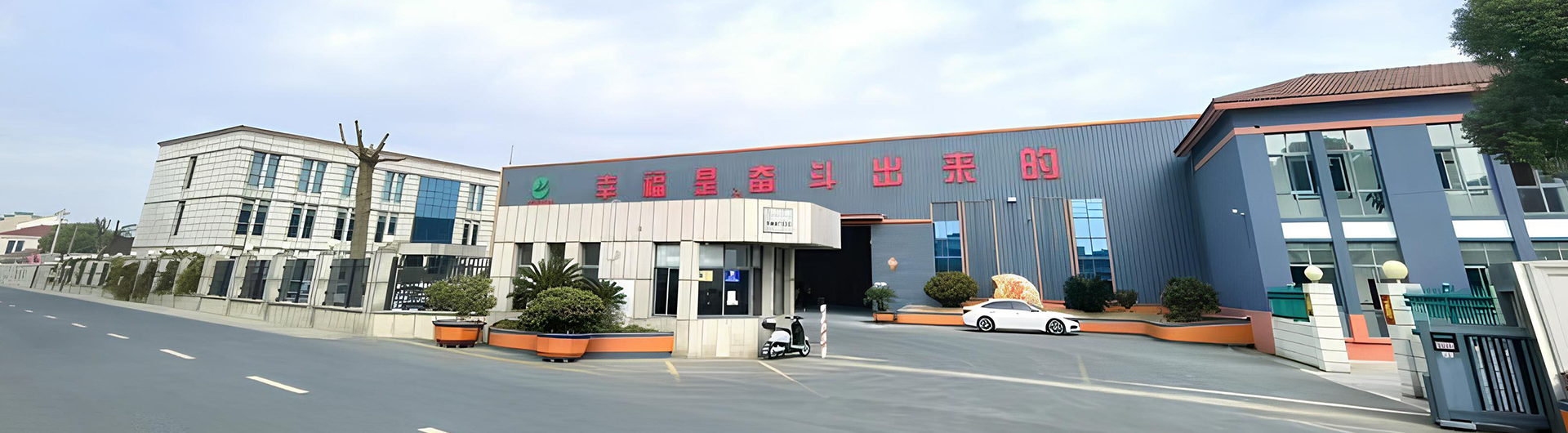

Shanghai Youlatong Industrial Technology Co., Ltd. is an innovative enterprise integrating aluminum material R&D, production, andengineering services. lt specializes in full-chain solutions forarchitectural aluminum panel decoration systems. With the Yangtze RiverDelta as its core market, the company has over a decade of industryexperience, completing over 100 projects in commercial complexes, high-end residences, and public spaces. Leveraging technology as its corecompetitiveness, it offers customers full-process services fromcustomized design to installation, supported by intelligent productionlines and an independent R&D team.

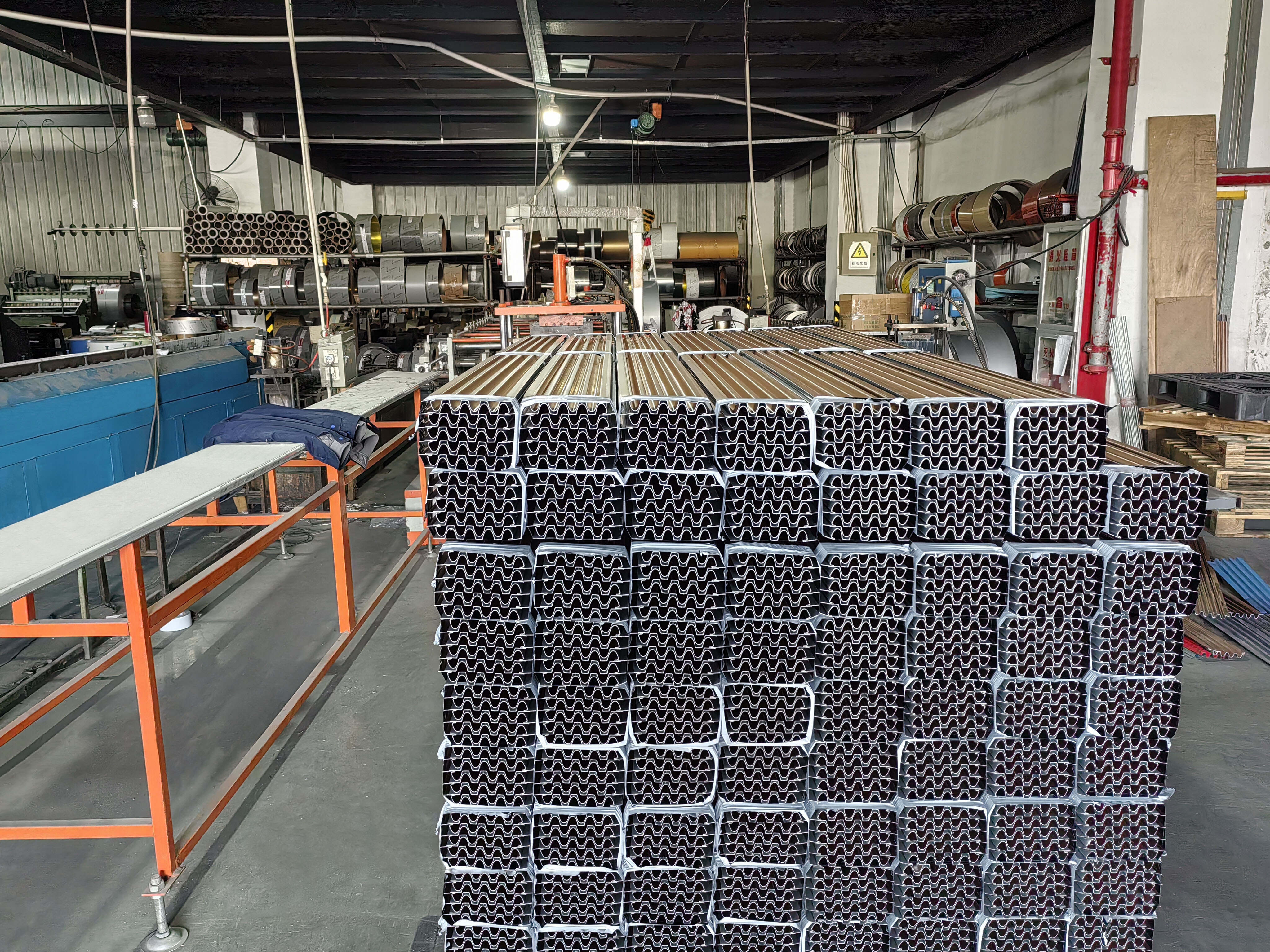

Facility Size: Over 10,000 square meters.

Production Staff: 38 employees.

Automated Processing Equipment: 42 sets.

Including:

130-ton 4+1-axis metal bending machine, capable of bending single plates up to 8,000 mm in length.

10,000W high-power fully automatic laser cutting machine.

Fully automatic turret punch press.

Fully automatic aluminum plate engraving machine.

Aluminum coil leveling and cutting machine.

Integrated extrusion molding machine for square tubes.

Fully automatic spraying and transfer printing production lines.

Raw Material Inventory: Over 200 tons of aluminum base material in stock.

Daily Production Capacity:

Aluminum plates: Approximately 1,000 square meters.

Aluminum square tubes: Over 6,000 meters.

Equipped with a professional product laboratory.

Strictly adheres to the ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and national environmental protection standards.

Maintains a highly skilled technical team and manufacturing workforce, ensuring product dimensional accuracy with errors strictly controlled within 0.1 mm.

4+1-axis bending machine:

Enables multi-angle precision bending.

Turret punch press:

For high-efficiency hole punching and shaping.

Extrusion molding:

Ensures consistency in square tube profiles.

Transfer printing:

Used for wood grain or custom surface patterns on aluminum.

This translation emphasizes precision, scalability, and compliance with international standards, suitable for international client or partner presentations.

Our team comprises 56 industry elites spanning four core domains: R&D design, production technology, quality inspection, and engineering services. Leveraging robust expertise and extensive practical experience, we deliver high-quality aluminum material solutions to our clients.

Design Team (5 members):

Consisting of 3 senior designers with over 10 years of experience and 2 assistant designers, this team excels in integrating architectural aesthetics with functionality. By closely tracking global aluminum application trends monthly, they have successfully developed 8 innovative product series, including stone-pattern and wood-grain transfer finishes, catering to personalized demands across diverse scenarios such as commercial complexes and residential projects.

Production & Quality Control Team (38 members):

This team includes 5 senior technical engineers and 23 production operation specialists, averaging over 8 years of industry experience. They master 18 precision processes, including aluminum plate bending, welding, and spraying, ensuring product dimensional accuracy within 0.1mm tolerance. Supported by 3 senior quality inspectors and 4 testing equipment specialists, the team rigorously adheres to ISO 9001 standards. Utilizing 12 advanced instruments such as spectrometers and salt spray test chambers, they conduct 26 critical inspections covering raw material composition, coating adhesion, and impact resistance, achieving a 99.6% product pass rate over the past three years.

Engineering Service Management Team (5 members):

Led by 6 seasoned on-site construction managers, this team provides end-to-end services from detailed drawing optimization to installation and final acceptance. Their expertise ensures seamless project execution and exceptional technical support throughout the entire lifecycle.

Sea container shipping

Sea-rail intermodal transport

Americas:

30-45 days

Europe:

35-45 days (standard) / 25-35 days (via China-Europe Railway)

Southeast Asia:

10-15 days (standard) / 9 days (via China-Laos Railway + sea shipping)

Middle East:

20-30 days

Moisture-proof sealing:

Use wooden crates or steel-frame structures lined with moisture-proof film, externally wrapped with waterproof tarpaulin to prevent oxidation from humidity.

Anti-collision design:

Aluminum honeycomb panels: Fixed with foam boards or honeycomb cardboard interlayers.

Aluminum (ceiling panels):

Individually packed in cartons before consolidated.

Clear labeling:

Mark product model, quantity, destination, and include "Fragile" and "Keep Dry" labels.