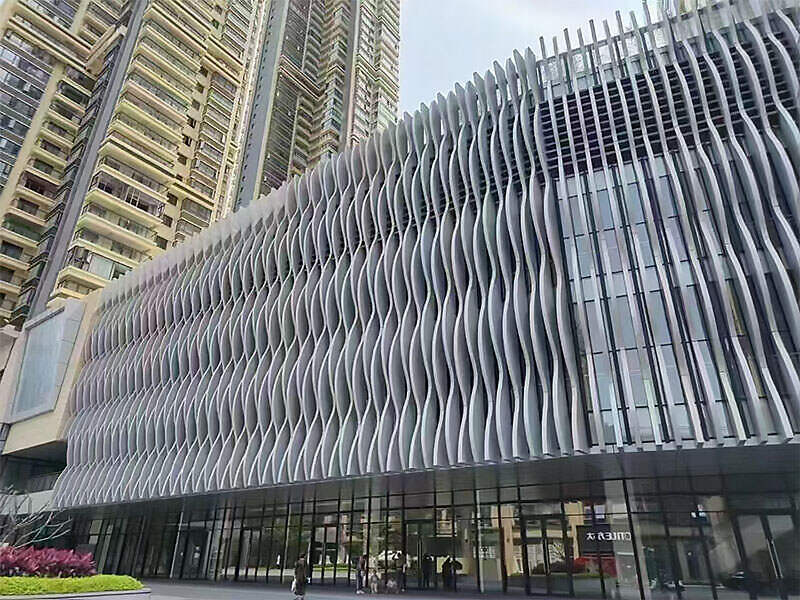

Shanghai Youlatong Industrial Technology Co., Ltd. is an innovative enterprise integrating aluminum material R&D, production, andengineering services. lt specializes in full-chain solutions forarchitectural aluminum panel decoration systems. With the Yangtze RiverDelta as its core market, the company has over a decade of industryexperience, completing over 100 projects in commercial complexes, high-end residences, and public spaces. Leveraging technology as its corecompetitiveness, it offers customers full-process services fromcustomized design to installation, supported by intelligent productionlines and an independent R&D team.

Product Category

Manufacturing Process

Cutting

CuttingAccording to the size of the drawing with a shearing machine or laser cutting machine to cut aluminum plate, special shape or ventilation holes, using CNC punch or engraving machine processing.

Forming Process

Forming ProcessThe aluminum sheet is folded into the design shape (such as arc, right Angle, etc.) by CNC bending machine.

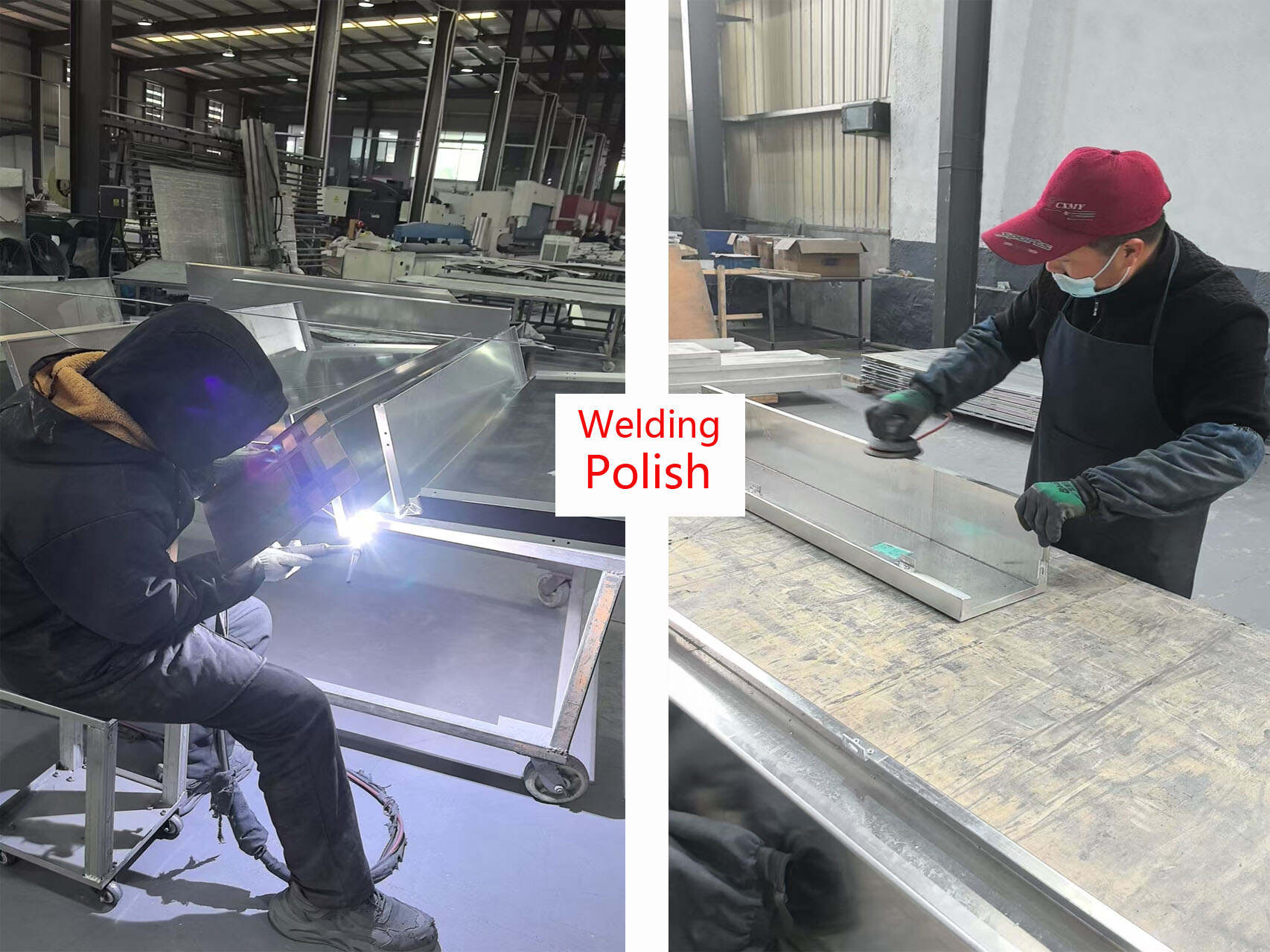

Arc rolling: The arc rolling machine into a cylindrical or curved shape. Welding And Strengthening

Welding And StrengtheningGroup welding: Complex structures need to be welded and spliced, and argon arc welding is used to ensure strength.

Reinforcement: Back welded reinforcement (corner code or keel) to improve deformation resistance. Surface Treatment

Surface TreatmentCleaning: Alkali washing to remove oil, pickling (chromified/chromium-free passivation) to enhance adhesion.

Drying: Ensure that the surface is dry and free of impurities. Coating Process

Coating ProcessSpraying: Electrostatic spraying primer → fluorocarbon top paint → varnish (strong weather resistance).

Anodizing: Electrolysis to form an oxide film to improve wear resistance.

High temperature curing: After spraying, enter the baking oven (180~250℃) to cure the coating. Quality Inspection

Quality InspectionSize inspection: Check whether the length, width and bending Angle conform to the drawing.

Coating test: Film thickness (≥30μm), color difference, adhesion (grid test), corrosion resistance (salt spray test).

Strength test: Check the stability of welding points and stiffeners.